The agricultural sector is undergoing a rapid transformation, driven by the urgent need for increased productivity, efficiency, and sustainability. Precision agriculture, drone-based crop monitoring, automated harvesting, and robotic application of fertilizers and pesticides are no longer futuristic concepts – they are rapidly becoming essential for modern farms. At the heart of this automation revolution lies reliable and efficient power transmission, and one of the key components in achieving this is the gear motor. Choosing the right gear motor is paramount for the success of any agricultural machinery upgrade project, significantly impacting performance, longevity, and ultimately, return on investment. This guide provides a comprehensive overview of gear motor selection, focusing on power and speed ratio matching for agricultural applications, and highlighting why selecting the right motor is essential in today's landscape of increasing resource demands and technological advancements.

Several factors are converging to fuel the demand for agricultural automation. Global population growth necessitates increased food production, while labor shortages and rising labor costs make traditional farming practices unsustainable. Furthermore, concerns about environmental impact are driving the adoption of precision agriculture techniques that minimize waste and optimize resource utilization. The COVID-19 pandemic has further accelerated this trend, highlighting the vulnerabilities of reliance on manual labor and emphasizing the importance of resilient and automated systems. The pressure to meet these challenges is leading to significant investments in machinery equipped with advanced automation capabilities.

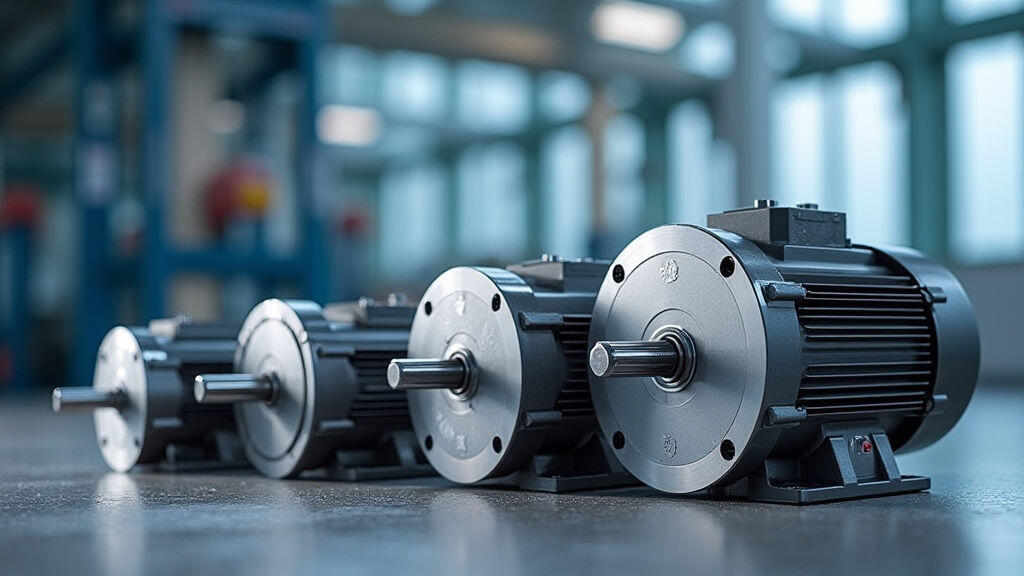

Gear motors are electromechanical devices that combine the functionality of an electric motor with a gearbox. This gearbox plays a vital role in modifying the motor’s output – reducing speed and increasing torque, or increasing speed and decreasing torque, depending on the application. In agricultural machinery, gear motors are widely used in a variety of applications, including:

The selection of a gear motor requires careful consideration of the load requirements of the application. The key parameters to focus on are power (measured in Watts or horsepower) and speed ratio, which dictates the relationship between the motor's input speed and the output speed of the gearbox.

1. Power Requirements:

The power required by the application depends on the torque needed to overcome the load and the desired operating speed. Torque is a rotational force, and it is crucial to choose a motor with sufficient torque to handle the application's demands. To determine the power requirements, a thorough analysis of the load is essential. This involves calculating the forces required to perform the task, considering factors such as the weight of the load, the friction in the system, and the acceleration/deceleration rates.

It's important to account for safety factors. A safety factor of 1.5 to 2.0 is generally recommended to ensure that the motor can handle unexpected loads or variations in operating conditions. For instance, a robotic arm used for harvesting crops might experience fluctuating loads due to inconsistent crop sizes or unexpected obstacles.

2. Speed Ratio:

The speed ratio is the ratio of the output speed to the input speed. A higher speed ratio means a lower output speed and a higher output torque. A lower speed ratio means a higher output speed and a lower output torque. The ideal speed ratio depends on the specific requirements of the application.

Matching Power and Speed Ratio:

The critical task in gear motor selection is finding a balance between power and speed ratio. This involves performing the following steps:

MES-Drive is committed to providing high-quality, reliable gear motors tailored for the demanding requirements of the agricultural industry. We offer a wide range of gear motors with varying power ratings, speed ratios, and customization options. Our team of engineers can assist in selecting the optimal gear motor for your specific application. We also offer comprehensive technical support and after-sales service to ensure the long-term performance and reliability of our products. MES-Drive’s motors are designed to withstand harsh environmental conditions commonly found in agricultural settings, including dust, moisture, and temperature fluctuations.

The future of agricultural automation is intertwined with the development of smart and connected machinery. Predictive maintenance, remote monitoring, and data analytics will allow farmers to optimize the performance of their equipment and proactively address potential issues. Gear motors are playing an increasingly important role in these advancements.

As the agricultural sector continues to embrace technologies like the Internet of Things (IoT) and artificial intelligence (AI), gear motors will become more sophisticated, incorporating sensors and communication capabilities. This will enable real-time monitoring of motor performance, allowing for predictive maintenance and optimized control strategies. Furthermore, advancements in motor control techniques, such as variable frequency drives (VFDs), will allow for precise control of motor speed and torque, further enhancing energy efficiency and performance.

The successful adoption of agricultural automation hinges on the selection of robust and efficient gear motors. By carefully considering power requirements, speed ratio, and application-specific needs, farmers and agricultural machinery manufacturers can ensure that their investments in automation deliver maximum value. As the industry moves towards increasingly sophisticated and interconnected systems, gear motors from companies like MES-Drive will continue to be essential components in driving productivity, efficiency, and sustainability in agriculture. With the focus on increased food production, resource optimization, and resilience in the face of climate change, the demand for reliable and intelligent gear motor solutions is set to grow significantly in the coming years. Selecting the right gear motor is no longer just about choosing a component – it’s about investing in the future of farming.

Leave A Reply

Your email address will not be published. Required fiels are marked